You’ve seen my requests for information on the GRC-215 man pack recently.

The GRC-215 is an unusual set. It seems like almost an afterthought that it was made into a portable set. I’ve been interested but several have told me that it is built of potted modules and unrepairable so I’ve stayed away.

This turns out to not be true.

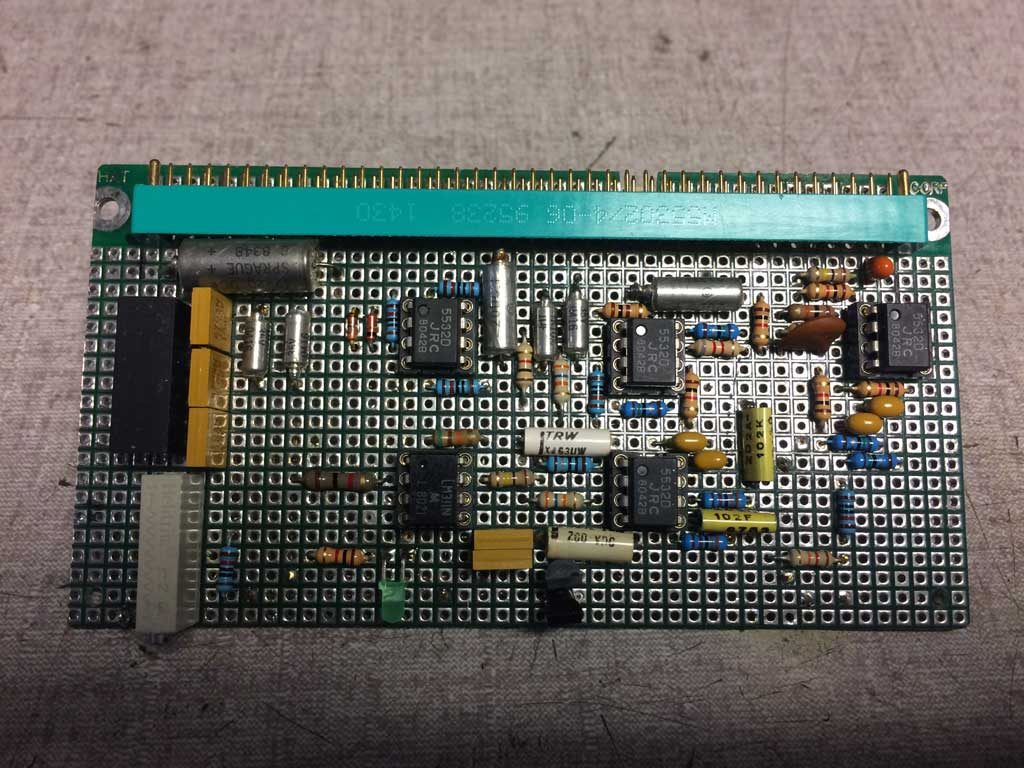

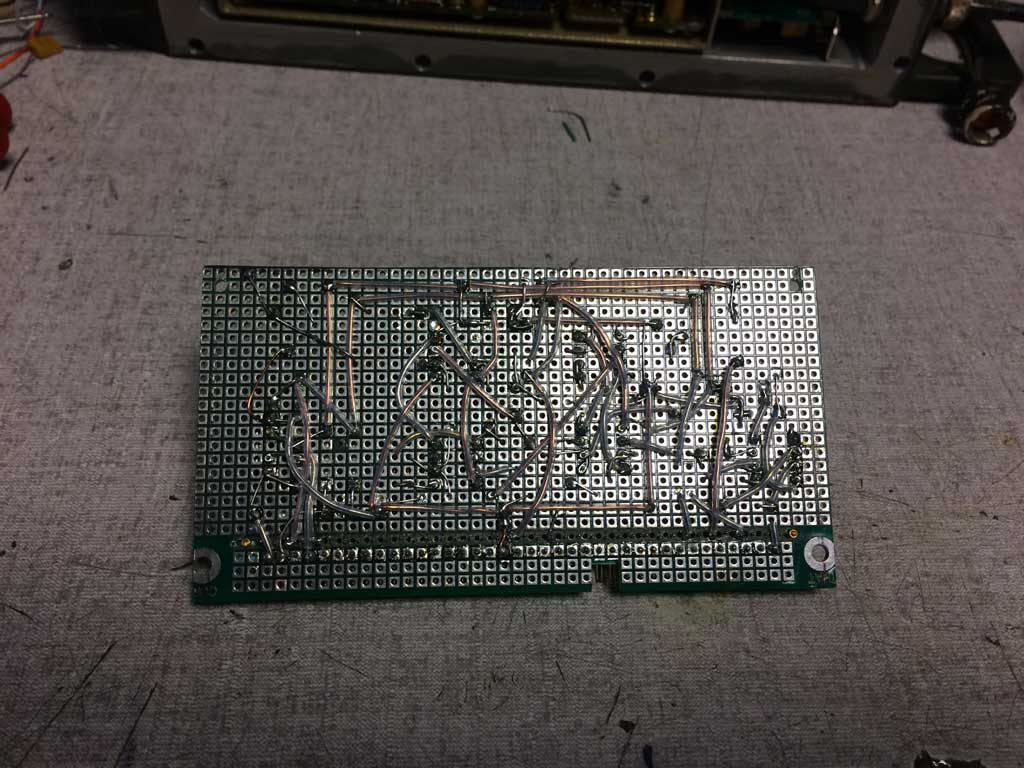

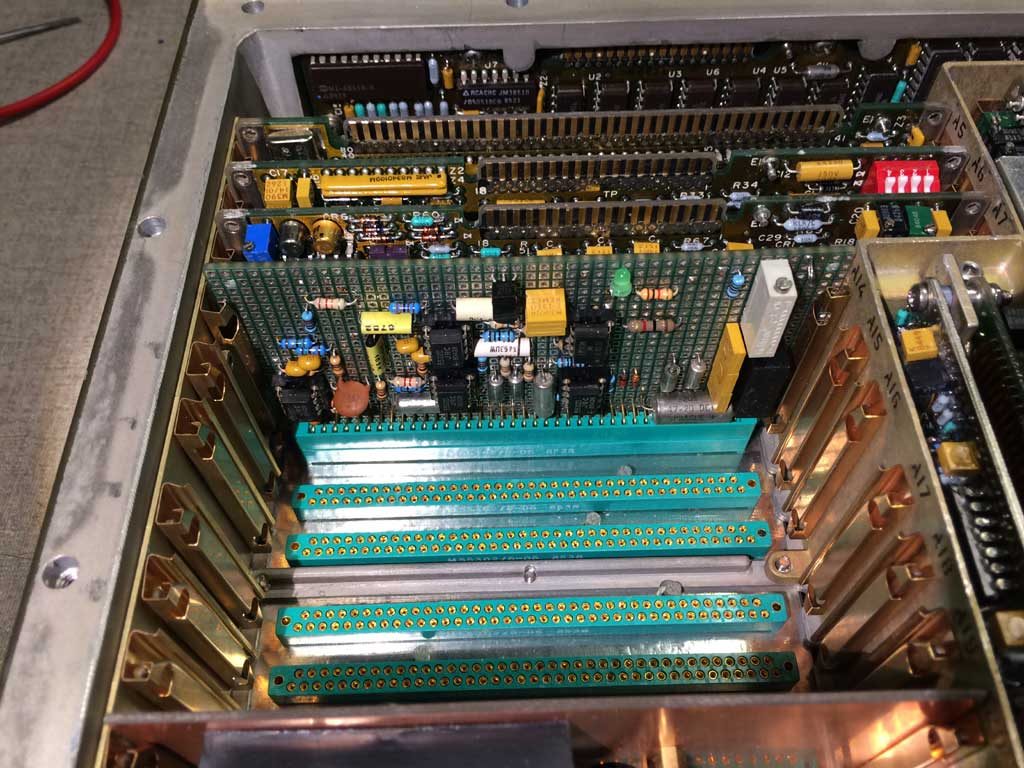

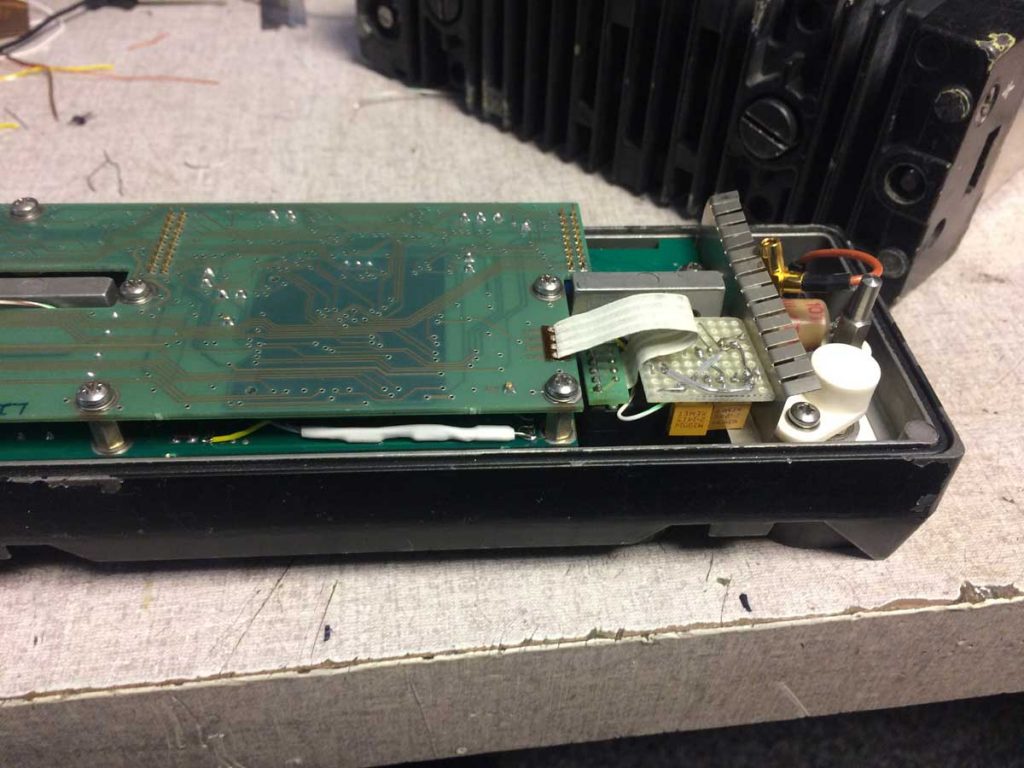

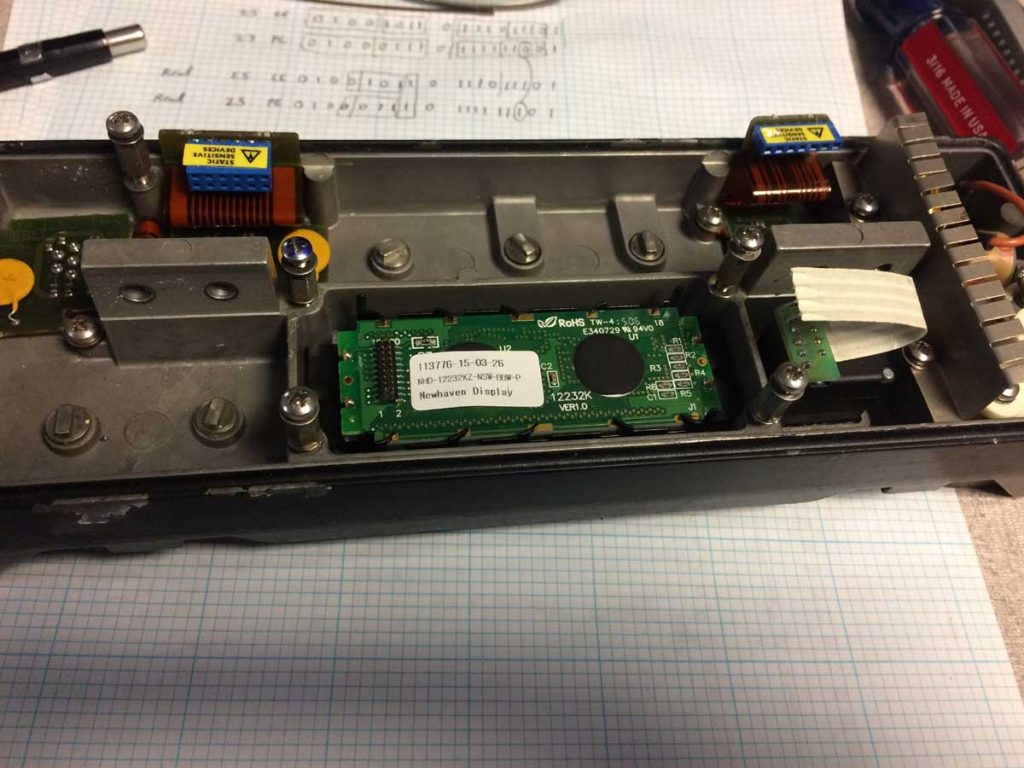

In any case, I had the opportunity to acquire one of these sets for a reasonable price, except it had a problem which seems to be an ATU tune failure. Photos of the inside showed that the guts were not potted but rather conventional design so I went for it.

I found that detailed service information is EXTREMELY hard to find, most notably schematics. A kind soul has sent me the module level manuals, which curiously have PCB component location diagrams and parts lists, but no schematics! There is a general module wiring diagram with labelled signals included.

***

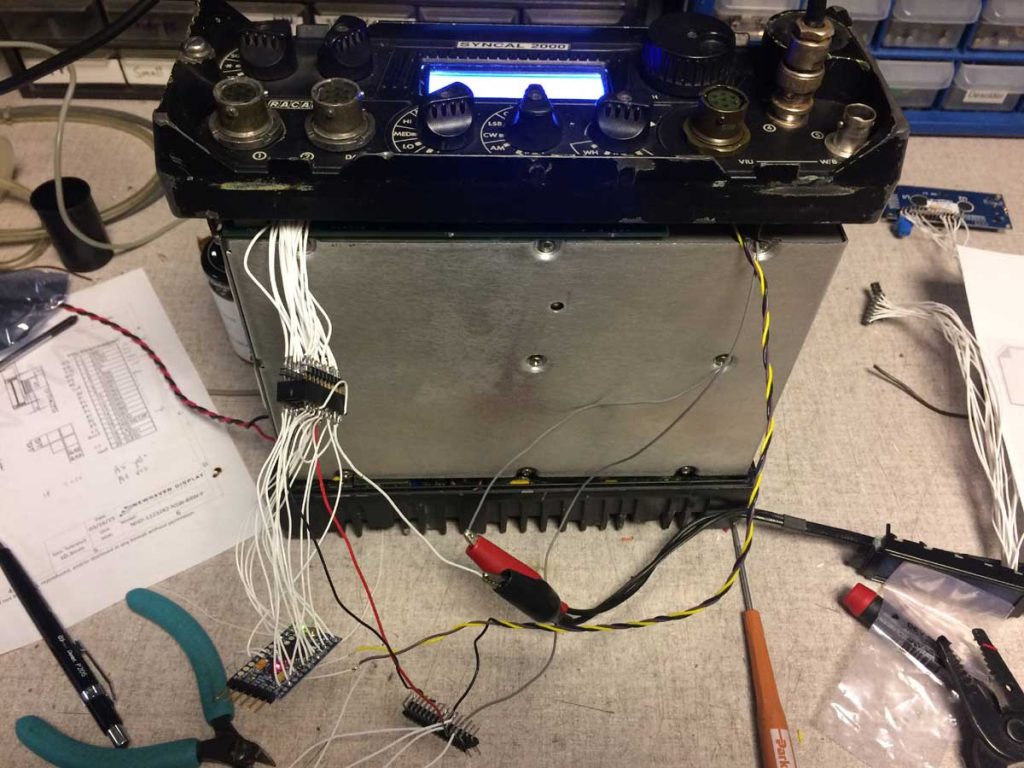

The fault is indeed that the ATU does not tune, but oddly enough, the tuner tries even when it’s not supposed to, when no whip is attached.

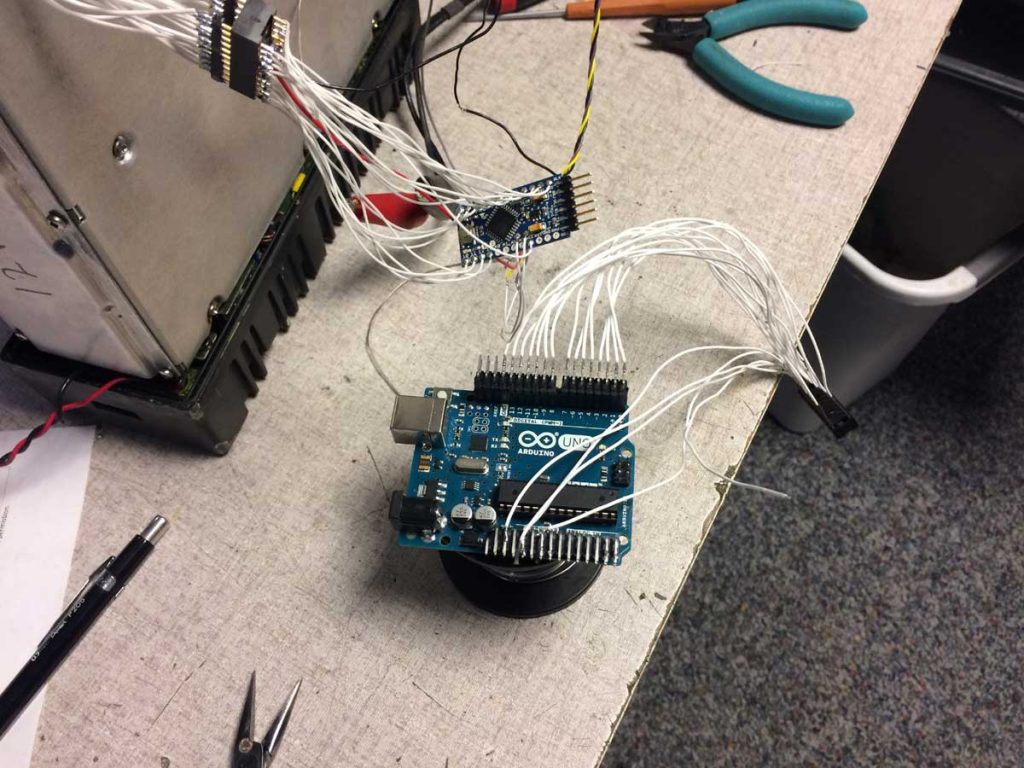

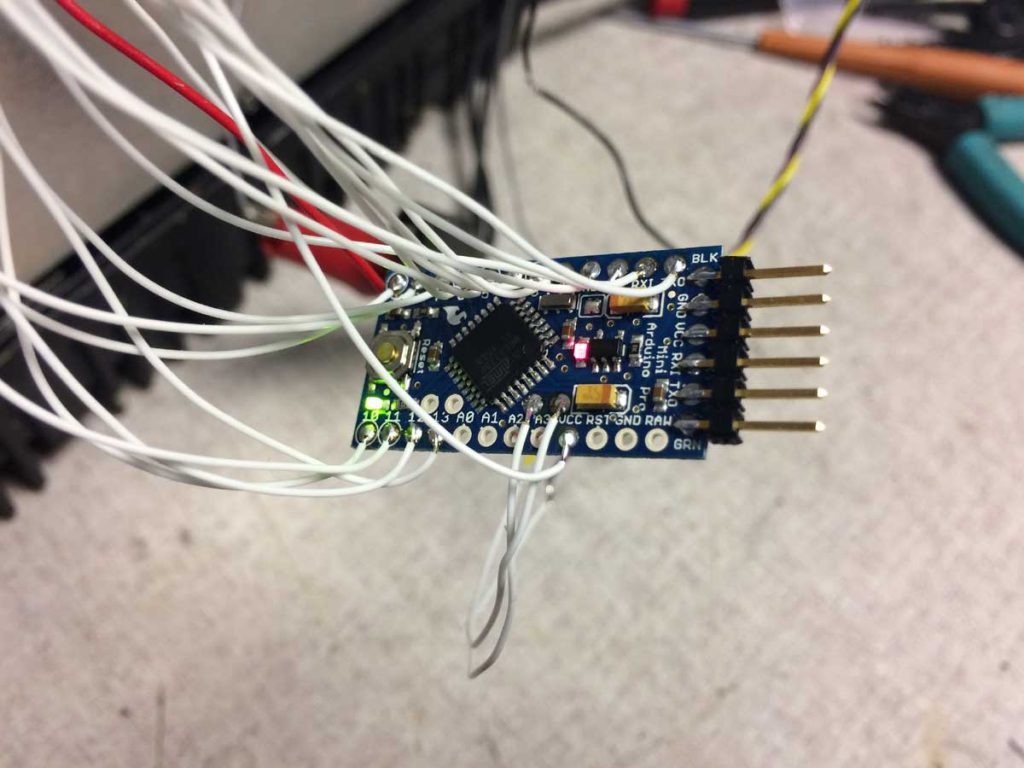

I made up a 25 pin D connector extension cable to operate the R/E with the ECCM control head detached.

After a little reading of the very basic qualitative circuit descriptions I understand that there is a “50 ohm” signal which comes from the ECCM unit to tell the switching logic to send the PA output to the BNC connector and disable the ATU. As the ATU always seems to run, I took a look at this signal and it indeed is always indicating to (falsely) use the tuner. That’s a problem.

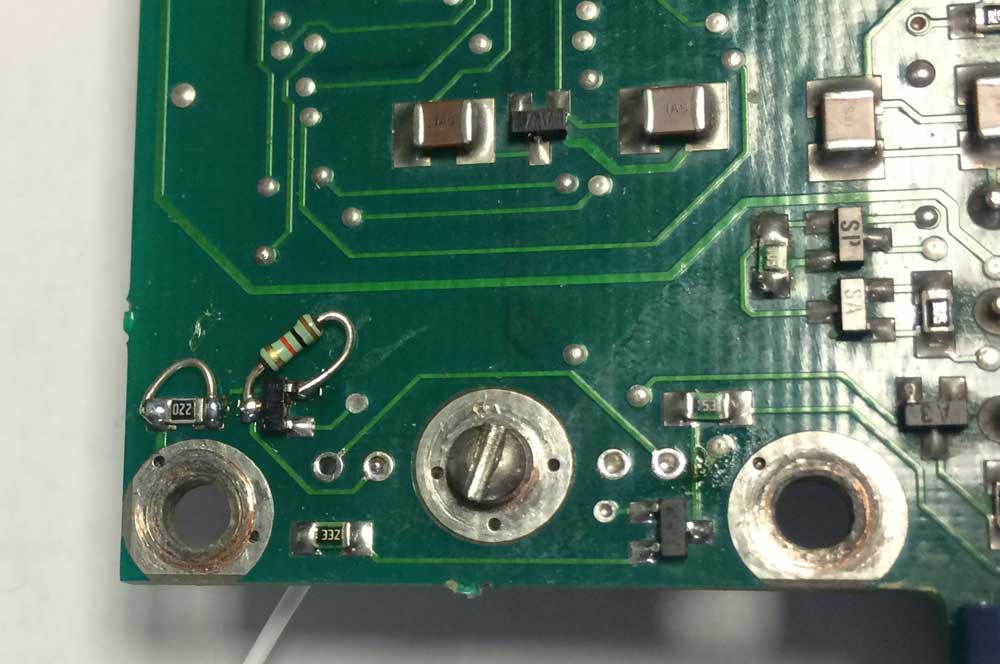

But where does this signal come from? There is a switch in the whip connection which activates when a whip is attached, but all that seems to do is make the RF path to the whip. There is a capacitor to a coax back to switching relays but no sense connection. How does the ECCM know whether a whip is connected or not? There is no explanation of how this works that I can find in the manuals, and it definitely isn’t working.

Well, what about if I just attach a whip? Tried that, same ATU fail problem.

Here’s a weirdness: not knowing how the radio works I placed a wattmeter and dummy load on the BNC connection. During the tune cycle the power goes up to about a watt before ending in failure. Why would the tuner affect the 50 ohm output? And what’s with the 1 watt?

I am suspecting a PA problem now. In low power mode there should be 5 watts out. Was the PA damaged by a problem in the antenna switching leading to running into an open? That’s pure conjecture. But very low tune power could definitely lead to faults being registered and tune failure.

So I decided to see what happened if I changed that 50 ohm signal. Since I have the ECCM on an extender cable I disconnected that signal and grounded it. First I did it the wrong way and nothing changed (duh) but I realized my stupid mistake and grounded the correct side and sure enouth the tuner doesn’t run and I get the full 1 watt on the BNC right away.

So the handset is specially wired and called a H-356. Modifying a H-250 is tough as there aren’t enough wires in the cord but I found it is possible to modify a H-350 handset as used in those digital field phones.

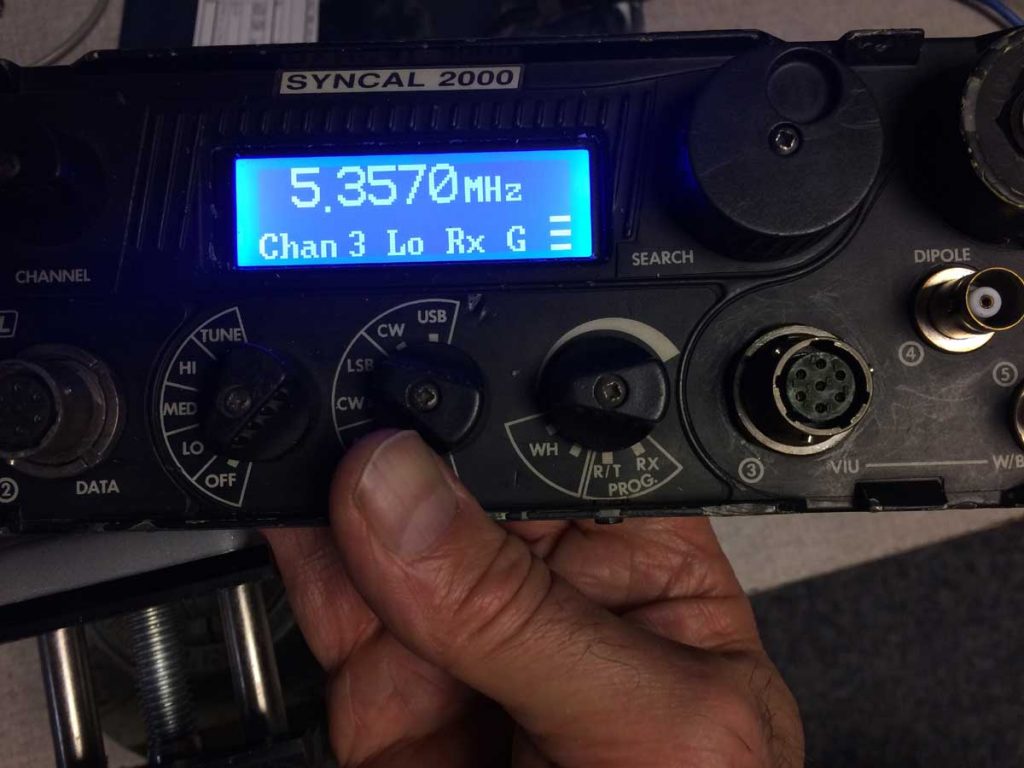

Looking on a scope there is a good SSB modulation, but only 1 watt. Going to high power gets to 5 watts. Should be 25.

So, one of the following:

1) PA problem

2) drive problem

3) control problem

4) harmonic filter problem

I tried on a bunch of different frequencies and they all behave the same so I’m thinking it’s not #4 but I will still check.

Now I need to open the unit up enough to get some test points temporarily brought out when I put it together and look at maybe the ALC first, then undo and extend the little coax in and out connectors to the PA itself and measure those. That will be next!